Can sodium-ion starter batteries replace AGM batteries?

The eco-friendly sodium-ion starter batteries are attracting more attention from potential consumers. One of frequently asked questions: Can sodium-ion starter batteries replace AGM batteries and be fully compatible with alternators and other onboard electronic devices? To answer this question, we can conduct a comprehensive analysis of sodium-ion batteries from several perspectives: their charge and discharge characteristics, temperature adaptability, cold cranking capability and life cycle.

1. Charge and discharge characteristics of sodium-ion starter batteries

The charging voltage range of the 12V sodium-ion starting battery is 8V-15.4V, which covers the voltage range of AGM batteries. Because the sodium-ion battery is equipped with a built-in intelligent battery management system (BMS), it ensures that the alternator cannot overcharge it.

The 12V sodium-ion starter battery has a discharge voltage range of 0V-15.4V, which also covers AGM batteries. Sodium-ion batteries are not afraid of over-discharge. Even if a sodium-ion battery is discharged to 0V and stored for a few months, its capacity still can be recovered to initial capacity after recharging.

Sodium-ion starter batteries have excellent charge and discharge performance. They can support 3C-5C fast charging and 15C-20C cold cranking discharge. This is mainly attributed to the following factors:

1.1 The solvation energy of sodium-ion batteries is low

The solvation energy of Na⁺ in the electrolyte (i.e., the strength of the bond between the ion and the solvent molecules) is very low. This means that Na⁺ is more easily desolvated (detached from the solvent molecules) in the electrolyte, resulting in less diffusion resistance at the electrode-electrolyte interface and faster interfacial reaction kinetics. This characteristic enables faster ion migration during high-rate charge and discharge in sodium-ion batteries.

1.2 Faster solid-phase diffusion kinetics

The crystal structure of electrode materials (such as hard carbon and layered oxides) can provide larger diffusion channels or lower diffusion energy barriers for Na⁺. For example, hard carbon anodes have open layered or nanoporous structures, allowing Na⁺ to be rapidly intercalated and deintercalated.

1.3 Fast interfacial charge transfer

The charge transfer resistance (charge transfer activation energy) between sodium ions and electrode materials is low, especially at the optimized electrode-electrolyte interface (such as when using carbon-coated or nano-sized electrode materials), which further reduces polarization and improves high-rate performance.

1.4 Stability of electrode materials

The electrode materials of sodium-ion batteries experience minimal volume changes during repeated charge and discharge processes, resulting in better structural stability. This makes the materials less likely to break or fail at high rates, maintaining a long cycle life.

The charge, discharge efficiency of sodium-ion batteries is much higher than AGM batteries. Sodium-ion starter batteries are fully compatible with alternators and other on-board electronic devices.

2. Temperature adaptability of sodium-ion starter batteries

Sodium-ion batteries have excellent temperature adaptability. The discharge temperature range is -40°C to 70°C, and the charge temperature range is -10°C to 60°C. The charge, discharge temperature range of sodium-ion batteries effectively covers the charge, discharge temperature range of AGM batteries.

The hard carbon anode used in sodium-ion batteries has a large interlayer spacing (0.37nm), which is conducive to the rapid insertion and deinsertion of sodium ions at low temperatures, avoiding volume expansion and kinetic hysteresis caused by low temperatures.

The hydrated ion radius of Na⁺ is small, resulting in a lower degree of solvation in the electrolyte. This reduces resistance to ion migration and allows for a high diffusion rate at low temperatures. Sodium-ion batteries typically use low-viscosity, low-melting-point electrolytes, which resist solidification at low temperatures and maintain high ionic conductivity.

The solid electrolyte interface (SEI) formed in sodium-ion batteries at low temperatures is more stable and less susceptible to shrinkage and rupture at low temperatures, which can lead to a sharp increase in interfacial impedance. Certain electrolyte additives can further optimize the low-temperature toughness of the SEI film.

In summary, the low-temperature performance advantage of sodium-ion batteries is the result of the synergistic effect of electrode materials, electrolyte formulation and interface.

3. Cold cranking capability of sodium-ion starter batteries

At -18°C, sodium-ion batteries maintain a stable and reliable 15C pulse discharge capability, providing ample support for vehicle starting. At -18°C, sodium-ion batteries maintain a discharge efficiency of over 85%, while AGM batteries only have a 50%-70% efficiency.

AGM batteries should be fully charged when parked in cold winter. Because a fully charged AGM battery has a freezing point of -40°C, while a low SoC AGM battery has a freezing point of only -10°C. Freezing can damage the separators, or plates of an AGM battery. Sodium-ion batteries can be stored in temperatures as low as -40°C at any SoC without freezing.

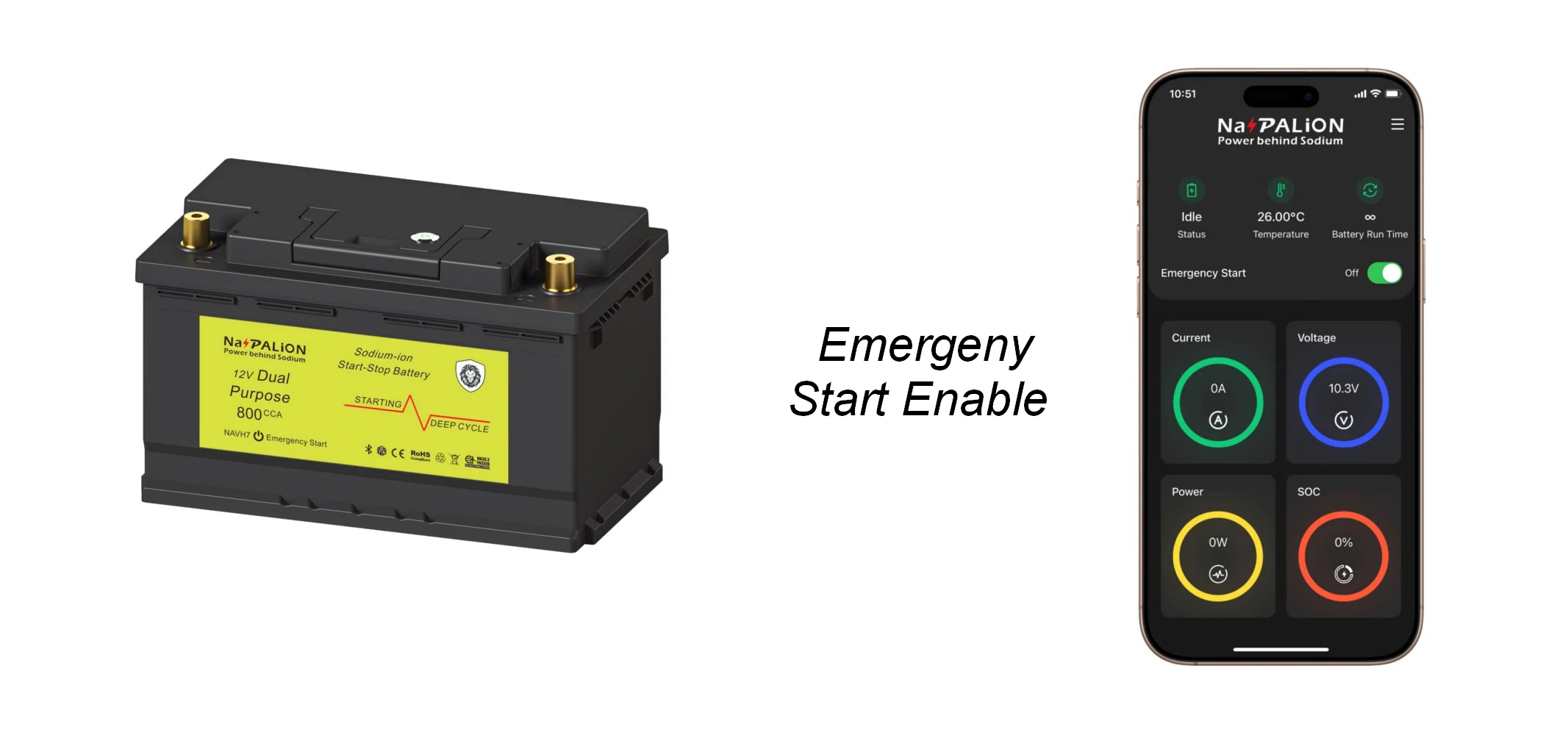

The NaPALION sodium-ion starter battery, equipped with an intelligent battery management system (BMS), features a emergency start function. This function ensures that when the battery is at low SoC, once the emergency start button is activated, giving the battery ability to start the vehicle.

4. Life cycle of sodium-ion starter batteries

The purpose of vehicle start-stop systems was to reduce fuel consumption and emissions. However, in reality, most users choose to disable them. Statistics show that the average fuel savings from start-stop systems is 3%. Considering the high cost of AGM batteries and their limited lifespan of 500 cycles, the fuel savings from the start-stop system are almost equivalent to the purchase cost of the AGM battery. It's no wonder that most users choose to disable them.

Sodium-ion starter batteries have a life cycle of up to 2,000 times, four times that of AMG batteries. A comprehensive comparison of the cost per use of sodium-ion starter batteries and AGM batteries reveals that sodium-ion batteries are only 50% of the cost of AGM batteries. The fuel savings from using sodium-ion starter batteries over their lifespan significantly exceed their purchase cost. They also effectively reduce exhaust emissions, protecting the environment of our community.

Based on the above facts, it is easy to conclude that sodium-ion starter batteries can replace AGM batteries for vehicle start-stop systems, which is both technically and economically feasible.

About DEFORD New Power Co., Ltd.

DEFORD New Power Co., Ltd. is committed to design and manufacture advanced, safe and reliable lithium-ion, sodium-ion battery systems. We are veterans of battery industry, and our core team has more than 20 years battery expertise.

Thanks to our deep understanding to battery technology, battery management system (BMS), and expertise on mechanics and thermodynamics. With the assistance of our advanced manufacturing facilities and cloud-based manufacturing execution system (MES). We do have the ability to guarantee the high quality, safety and reliability of your battery systems.

For any inquiries about sodium-ion starter batteries, please contact us by info@deford.com.cn.