How lithium or sodium-ion batteries help AGV, AMR to improve productivity and save cost? Compare with traditional lead acid batteries, lithium or sodium-ion batteries require ZERO daily maintenance. Lithium or sodium-ion batteries do not require daily watering or swapping at shift changes, so companies do not need to schedule labor for this work or plan facility space around battery charging/changing rooms. The increased uptime that is achieved with the switch to lithium or sodium-ion batteries similarly meets this need for increased productivity of equipment when demand is higher. With lithium or sodium-ion battery technology, an AGV, AMR can operate on a single battery with opportunity fast charging, and reach full charge in 20 minutes when needed. In comparison, traditional lead acid batteries take eight to ten hours to charge and require two or more batteries per AGV, AMR.

As the use of AGV, AMR, and the like increases in the field of material handling, lithium or sodium-ion batteries become more and more popular because they are the best choice for this type of equipment, flexible charging patterns and fast charge ability makes AGV, AMR to work above 20 hours in each working day becomes feasible.

How to design an advanced battery system for AGV, or AMR?

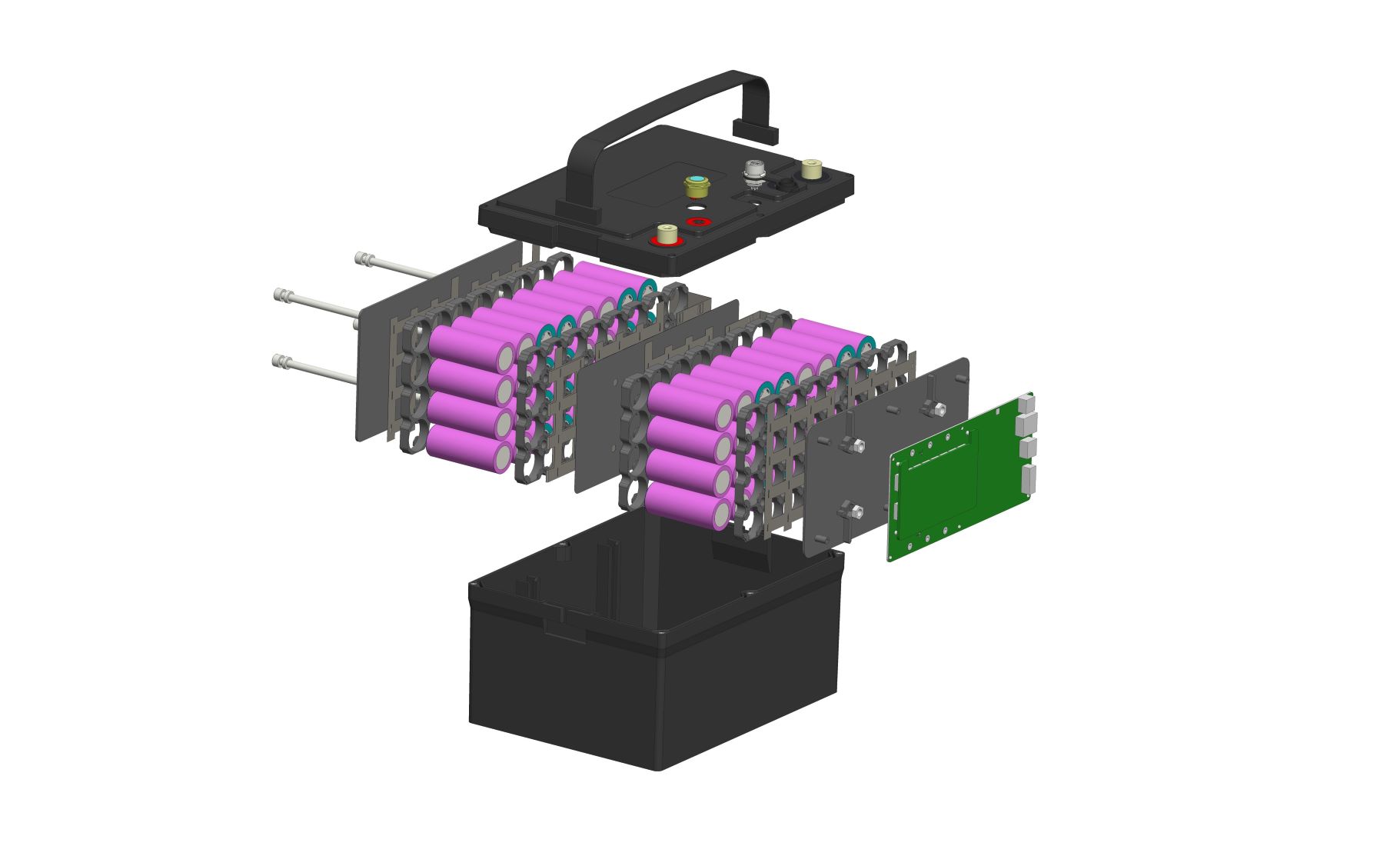

A battery system is composed of three critical parts like cells, battery management system and battery mechanics.

Our talented engineers are experienced in development, or selection of the parts.

Cell Selection

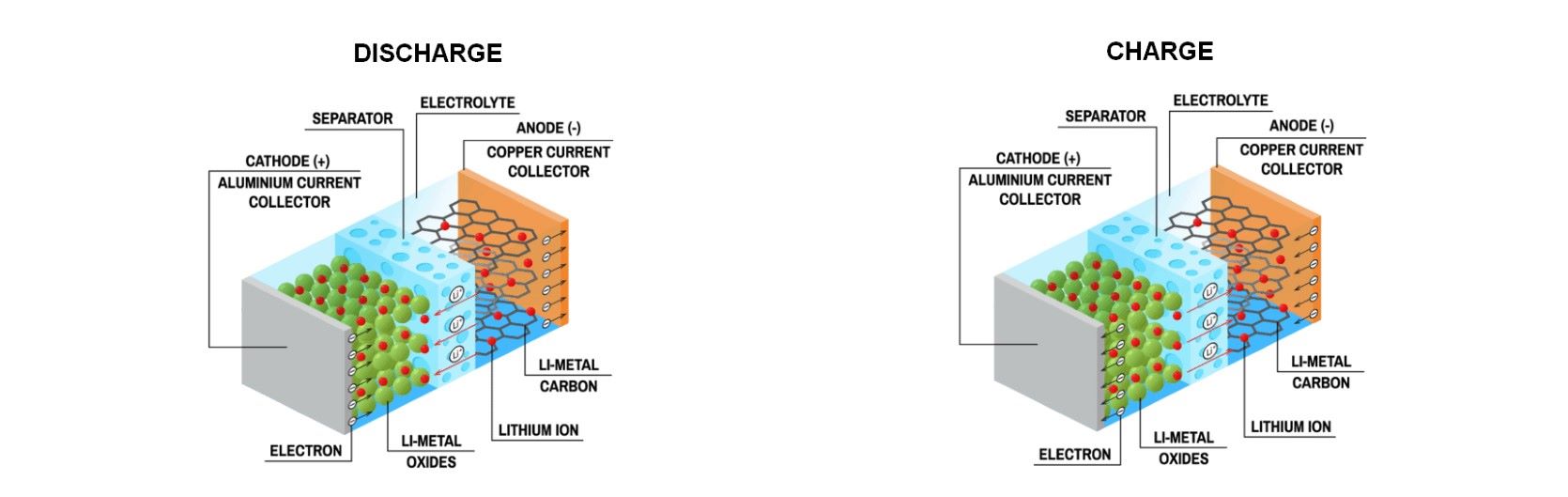

Our electrochemical engineers with more than 15 years’ experience are deeply understand all types of secondary battery chemistry, whether in pros or cons. They take so far the safest lithium iron phosphate chemistry, or sodium-ion chemistry cells to design and manufacture our highly reliable and safe battery systems widely used on AGV, or AMR.

BMS - Battery Management System

Battery management systems are electronic control circuits that monitor and regulate the charging and discharge of rechargeable battery systems. The lithium or sodium-ion battery characteristics to be monitored include the detection of battery chemistry, voltages, temperature, capacity, sate of charge (SoC), state of health (SOH), power consumption, remaining operating time, charging cycles, and some more characteristics. Our talented electrical design engineers with more than 10 years’ experience are up to the challenge to develop more efficient, longer-lasting and more reliable BMS in house.

Battery Mechanics

Most of battery systems are sensitive to work condition like mechanical shock and vibration, or temperature. It is a priority work to design a rugged battery case to protect cells and BMS away from possible mechanical shock and vibration damage. Meanwhile our mechanical engineers simulate battery thermal runaway according to DFMEA, especially when battery heat dissipation relys on natural convection. Keeping battery works in recommended temperature range is necessary to keep it high performance and long life.

How to monitor, or upgrade your battery systems for AGV, AMR?

Users can download the free LiAGE App from App Store, or Google Play to monitor their battery systems. The LiAGE App can provide battery real-time monitoring, or warning notification to users. Your battery reserves a data port on side which can be used to upgrade battery firmware through the bespoke battery monitoring software.

Find out your requested AGV, AMR battery in our 2026 catalog.

If you cannot find the proper model. Please leave your message to customize your battery.